Getting My Inventory Management To Work

Wiki Article

The 7-Second Trick For Inventory Management

Table of ContentsMore About Inventory ManagementExcitement About Inventory ManagementInventory Management Things To Know Before You BuyInventory Management Fundamentals ExplainedThe Main Principles Of Inventory Management

The routine inventory system is an approach of inventory valuation for economic coverage objectives in which a physical count of the stock is performed at particular periods. This accounting approach takes supply at the beginning of a period, adds brand-new supply acquisitions during the period and deducts finishing stock to derive the price of products marketed (GEARS).They can associate a number of data indicate the number, including the provider, product dimensions, weight, as well as even variable information, such as the number of are in stock. RFID or superhigh frequency recognition is a system that wirelessly transmits the identification of a product in the kind of an unique identification number to track things and also provide detailed product info.

Inventory Management Things To Know Before You Get This

Inventory monitoring describes the process of saving, ordering, and also marketing of items and also services. The discipline additionally involves the management of numerous supplies and also processes. One of one of the most important elements of supply monitoring is taking care of the circulation of raw products from their procurement to end up products. The goal is to minimize overstocks as well as boost performance to ensure that projects can remain on time as well as within budget.An oil depot can keep a big inventory for a long time. Or for businesses that handle subject to spoiling items, such as fast-fashion items, keeping on top of your supply can be very costly. One way to account for stock is by grouping it right into 4 categories: first-in-first-out, last-in-first-out, weighted-average, as well as first-in-first-out.

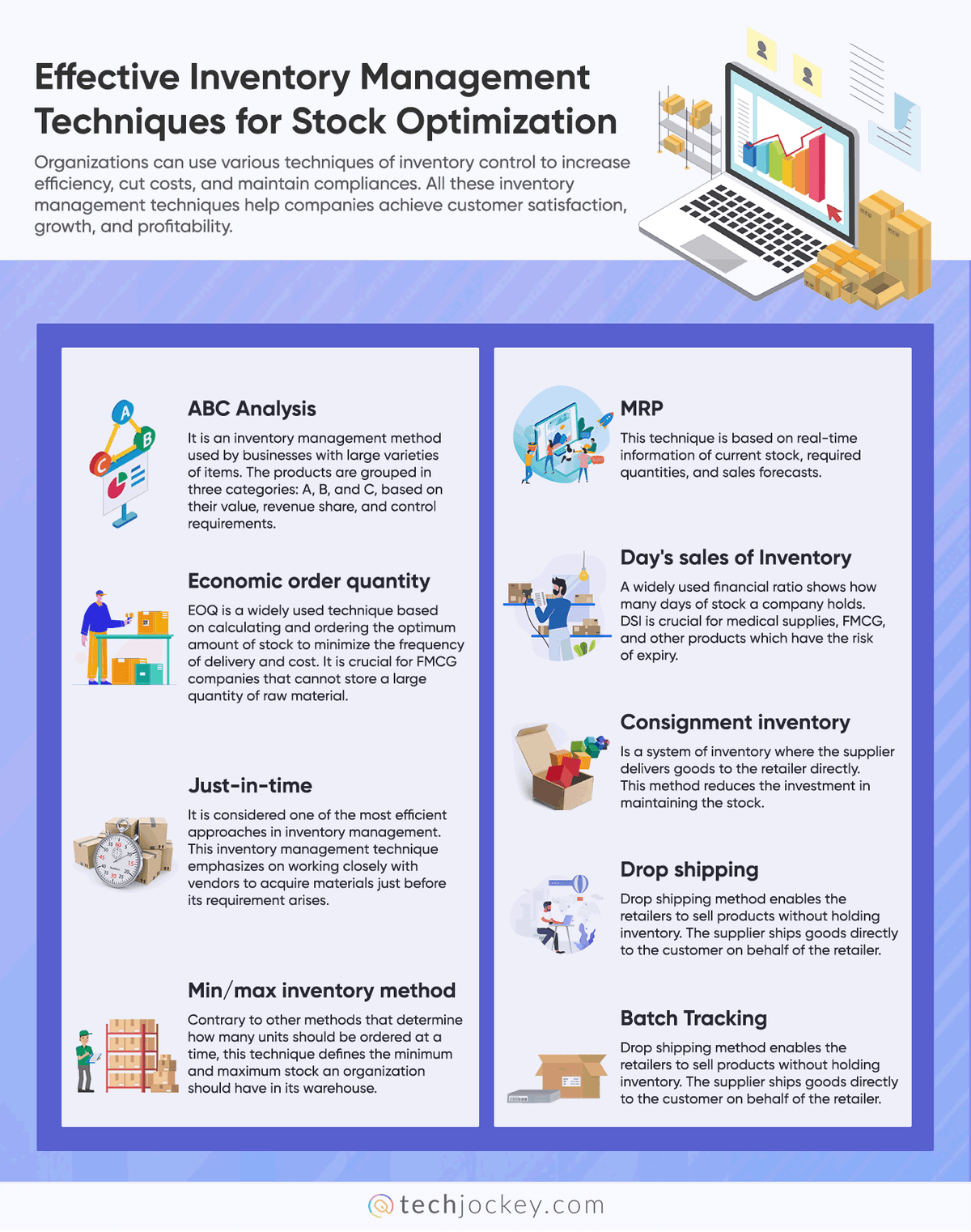

Depending upon the sort of company that it is managing, different stock administration methods are used. Some of these consist of JIT, product requirement preparation, and days sales of inventory. Other methods of analyzing supply can also be used depending upon nationwide and local laws. The SEC requires public business to report the existence of a supposed LIFO reserve.

Inventory Management - An Overview

Find out also extra concerning stock management from Walton College's Supply Chain Management program's intro on the subject covering whatever from projecting to aim models: Among one of the most useful possessions of a business is its supply. Inventory Management. In different industries, such as retail, food solutions, and production, an absence of stock can have destructive results.Having a huge supply can also lead to a reduction in sales. Both for little organizations as well as large corporations, having a proper supply administration system is very important for any business.

This is especially crucial for brands aiming to become a much more customer-centric company. Balancing the dangers of overstocks as well as shortages is an especially challenging process for business with intricate supply chains. A firm's stock is normally a current possession that it plans to market within a year. Inventory Management. It must be gauged as well as counted on a regular basis to be thought about an existing asset.

Some Known Facts About Inventory Management.

Not just will it offer to boost performance, but it's likewise valuable for avoiding theft with the assistance of item monitoring and also security. Managers can also aim to use their stock management strategy to keep an eye on sales procedures which leads to much better solution.

Providing customers several various kinds of internationally-grown fruit and vegetables in both natural as well as non-organic ranges at an economical rate, also when the vegetables and fruits aren't in season, is a contemporary marvel many thanks partly to stock monitoring. Managing stock in actual time and also even establishing automated replenishment systems is mission-critical to several.

The Definitive Guide for Inventory Management

Their Smart Warehouse utilizes robot and human help to click site get the work done, however it's stock monitoring that keeps it all rolling. The stock management of commode paper firms was in the warm seat in early 2020 as panic-buying led to shortages across the country.

Here are the major types you ought to know: Resources, This describes Visit Website pieces of your item that demand to be delivered to you as well as assembled by your group. Stock systems that track these must make up vendor timelines. Underway, Products made from raw materials as well as are currently being set up or grouped loss under this group.

Report this wiki page